▲ Enhance production capacity to provide high-quality surgical masks to Taiwan and the rest of the world throughout the pandemic

During the COVID-19 epidemic, Taiwan national mask production teams successfully broke through the production capacity limit within a short space of time. Through this feat, Taiwan has ensured a sufficient mask supply for all of Taiwan and the international community combined; becoming the world’s best model of epidemic prevention. The Taiwan Comfort Champ group has played a crucial role in preventing the spread of COVID-19, and they have set a record of 25% as its highest production capacity to become the number one mask producing company in Taiwan. With the ongoing global epidemic, prevention and control remains the key factor. The Taiwan Comfort Champ group will launch a one-stop mask manufacturing programme by adopting a total-solution approach starting from raw material procurement, providing essential machinery and equipment, combined mask production lines, and going all the way to quality assurance and testing. The concept of a one-stop mask manufacturing programme has integrated the upstream, mid-stream and downstream production chains which is receiving support from the Ministry of Foreign Affairs. Since June 2020, various overseas manufacturers have been referred by the Ministry of Foreign Affairs to replicate the success of Taiwan’s national mask production teams in the form of commercial cooperation. Mask manufacturers in Taiwan are willing to provide “crucial technology” support to enhance the quality of mask production with the main objective of producing approved masks that will help to prevent the spread of COVID-19.

During the COVID-19 pandemic, the Taiwan Comfort Champ group has received many inquiries from manufacturers both nationally and abroad who were showing an interest of investing in mask productions. Some of these manufacturers are facing hurdles in their mask production processes, among those being new start-ups in the mask industry who possess a limited knowledge regarding investment scale estimates and market needs. After examining their problems, the Taiwan Comfort Champ group has revised a module of the one-stop mask manufacturing programme to answer the questions of the international market and offer clarity, including:

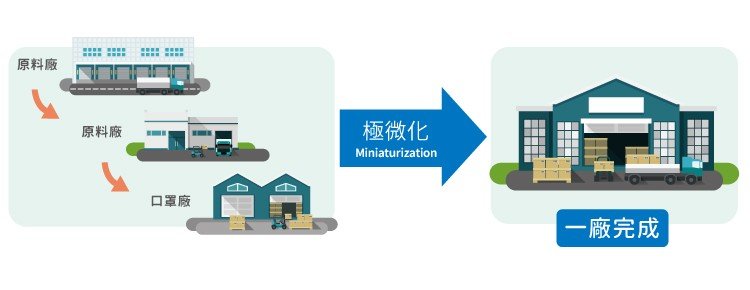

I. Miniaturization of the production chain:

With their industrial chain experience, the Taiwan Comfort Champ group can provide the smallest machinery and equipment that could fit into a nominal sized factory (actual figures shall be used to facilitate our work, e.g.: a reduction by 50%), It is estimated that manufacturers can produce 200,000 to 600,000 masks per day. Higher production capacity modules can also be provided for max 2 million masks according to the manufacturer’s needs.

II. Minimize investment scale:

Manufacturers can establish a one-stop production line that is coupled to a low investment scale.

III. Crucial technology support to improve quality assurance:

The COVID-19 outbreak has brought in numerous domestic and foreign manufacturers that invested in melt-blown, non-woven fabrics manufacturing. Although these manufacturers are equipped with the necessary machinery and equipment, they have utterly failed to produce satisfactory non-woven fabric that do meet the required industry standards.

The key material of a surgical mask is the melt-blown nonwoven fabric in the center of the mask, which serves as a filtration material. Technically, this material should be a medical-grade electrostatic melt-blown nonwoven fabric with a bacteria filtration efficiency exceeding 95%. The efficiency should last for a period of at least 5 years before it can be considered a qualified filter layer. This is why such technology is considered to be the best in the world. It is not easy for manufacturers of melt blown non-woven fabric to enhance the stability of electrostatic electret technology. The majority of melt-blown non-woven fabrics produced have an efficiency that only last for 1 to 2 years and some do not even fulfill the required standards at all. The Taiwan Comfort Champ group can provide crucial technological support to assist manufacturers in fulfilling the required standards.

IV. Sharing the successful experience & technical support:

A lot of manufacturers often encounter problems whereby the fabric bunches up when it is fed through the machine, which seriously affects the production schedule. Lacking the necessary experience of identifying good material attributes will also lead to failure when you are trying to produce approved masks. With all the experience acquired in mask manufacturing, the Taiwan Comfort Champ group can share its experience and provide technical support to novice manufacturers; and also able to provide the latest recyclable and patented flexible nose-strip to produce high-quality masks with low material costs.

V. Cost and Carbon Reduction:

The concept of combining mask production lines into a one-stop mask manufacturing programme has created multiple benefits. There is a great cost savings through a reduction in transportation costs of raw material, packing materials and labor costs that were previously expended. The Taiwan Comfort Champ group also reduces the carbon footprint and increases the environmental protection by this concept. “One-stop mask manufacturing programme” can provide various needs according to international market and manufactures demand. Three supply chains are available for investors in accordance with “Micro”, “Economy” and “Standard”.

The ability to prevent and control the spread of the COVID-19 pandemic has offered the world an appreciation of the quality products that are manufactured in Taiwan; overseas laboratories have also recognized the quality of masks manufactured in Taiwan. Chairman Andy Chen, of the Taiwan Comfort Champ group, has entered cooperation with Ben Hsiao, of NCM Nonwoven Converting Machinery Co., Ltd., to establish the one-stop mask manufacturing programme with the help of Trimeltech Co., Ltd (a subsidiary of the Taiwan Comfort Champ group), Win-Win Nonwoven Innovation Co., Ltd, and Changyu Co., Ltd. only a few months ago. By introducing vertical integration between industries and obtained key raw materials, manufacturers can produce approved surgical masks with relative ease. With the one-stop mask manufacturing programme, together with advanced technology and the successful experience of the Taiwan Comfort Champ group — Taiwan will surely attract global attention. By helping various countries to establish a good, first-protective net against the COVID-19 pandemic, Taiwan’s successful experiences can contribute to the betterment of health and wellbeing throughout the entire globe.